Before you start comparing the numbers, you need to determine the true energy efficiency of your building envelope, which is far more than just an insulation’s tested R-value. The whole-wall R-value is a more accurate measurement of the science behind real-world performance compared to the insulation’s R-value alone. Many studies show a building’s air tightness has more of an impact on energy efficiency than the R-value of the materials themselves. In fact, air leakage is responsible for 40% of heat/cooling loss (wasted energy).

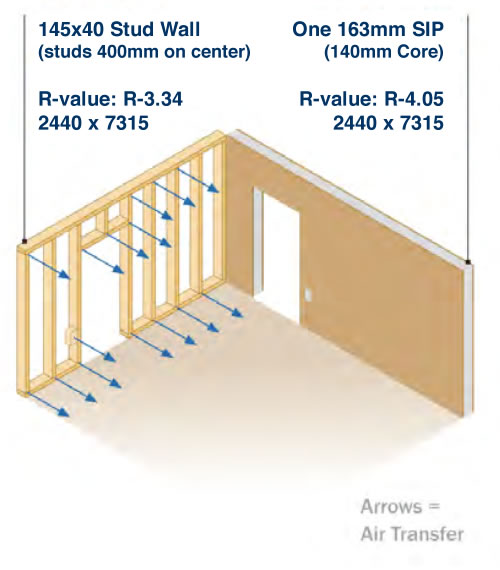

Air tightness in SIPs vs. Stick Frame:

In a study by the Department of Energy’s Oak Ridge National Laboratory, two identical test rooms were built side by side. One stick-framed, one SIP-framed. The rooms were tested for air infiltration and the SIP room was FIFTEEN times more air tight, and more energy efficient than the stick-framed room. This alone illustrates how critical air tightness is to a building’s energy efficiency. The science behind air infiltration in framing products explains the types of air movements and their effect on energy efficiency.

In a study by the Department of Energy’s Oak Ridge National Laboratory, two identical test rooms were built side by side. One stick-framed, one SIP-framed. The rooms were tested for air infiltration and the SIP room was FIFTEEN times more air tight, and more energy efficient than the stick-framed room. This alone illustrates how critical air tightness is to a building’s energy efficiency. The science behind air infiltration in framing products explains the types of air movements and their effect on energy efficiency.

Inevitable air leaks through joints and gaps.

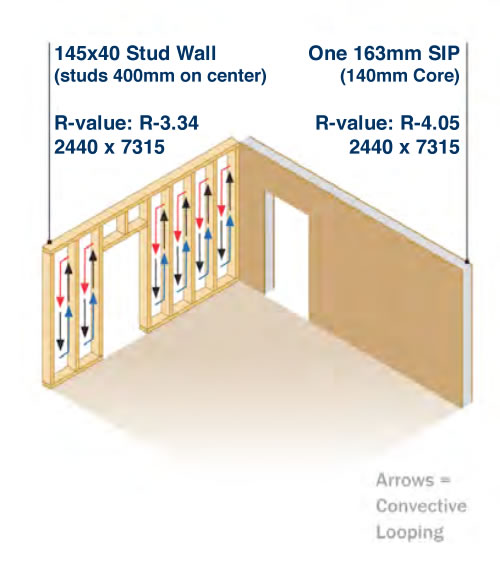

Warm air rises & cold air sinks in conventionally framed wall cavities, wasting valuable energy. Unless the insulation is solid to stop this air movement, it doesn’t matter what the insulation’s R- value is. SIPS’ solid insulation core, helps eliminate heat carrying air flow through the wall cavities.

Thermal Bridging:

Wood elements form a bridge between the inside & outside faces of a wall, allowing heat to pass through by conduction. Stick-framed buildings are 15-25% lumber, compared to as little as 3% in SIPS framed structures.

Wood elements form a bridge between the inside & outside faces of a wall, allowing heat to pass through by conduction. Stick-framed buildings are 15-25% lumber, compared to as little as 3% in SIPS framed structures.