Timber Framing to SIPS Framing Comparison

Based on a 2500 sq. ft. single storey home

| Stick Framing | SIPS Framing | ||

|---|---|---|---|

| Snap Lines | 1 Day | Snap Lines | 1 Day |

| Plate | 1 Day | Plate | 1 Day |

| Frame | 4 Days | Frame | 3 Days |

| Plumb & Line | 2 Days | Plumb & Line | 1 Day |

| Set Trusses | 2 Days | Set Trusses | 1 Day |

| Roof Sheet | 2 Days | Roof Sheet | 1 Day |

| Total = | 12 Days | Total = | 8 Days |

| Rough Trades/Ext. Walls | Rough Trades/Ext. Walls | ||

| Electrical/Drill Studs | 1 Day | Drill Studs | 0 Days |

| Framer/Furring Walls | 1 Day | Furring Walls | 0 Days |

| Framer/Shear Panels | 1 Day | Shear Panels | 0 Days |

| Insulate Walls/Ceilings | 1 Day | Insulation | 0 Days |

| Total = | 5 Days | Total = | 0 Days |

| Note: shear panels arrive pre-cut for windows and doors | |||

| Rough Inspections | Rough Inspections | ||

| Exterior Shear | 1 Day | Exterior Shear | 0 Days |

| Insulation Insp | 1 Day | Insulation Insp | 0 Days |

| Total = | 2 Days | Total = | 0 Days |

| Total Days = | 19 Days | Total Days = | 8 Days |

Note: Eleven days saved between snapping lines and drywall insulation.

Note: Additional times saved not having bowed wall or drywall cracking.

Note: Days will vary with size of home and weather conditions.

Money Saved using SIPS

Based on average prevailing wage

| Framer | ||

|---|---|---|

| 4 Days saved on labor | $27 per hr. | $864.00 |

| 3 man crew instead of 5 (1 Day) | $27 per hr. | $432.00 |

| 1 Day saved Furring walls | $27 per hr. | $216.00 |

| 2 Days saved shear panels | $27 per hr. | $432.00 |

| Total = | $1,944.00 | |

| Electrition | ||

| 1 Day saved on drilling studs | $25 per hr. | $192.00 |

| Total = | $192.00 | |

| Insulation | ||

| Money saved not installing in ext. walls | $800.00 | |

| Money saved not installing in ceilings | $600.00 | |

| Total = | $1400.00 | |

| Approximate savings per unit | Total = | $3,440.00 |

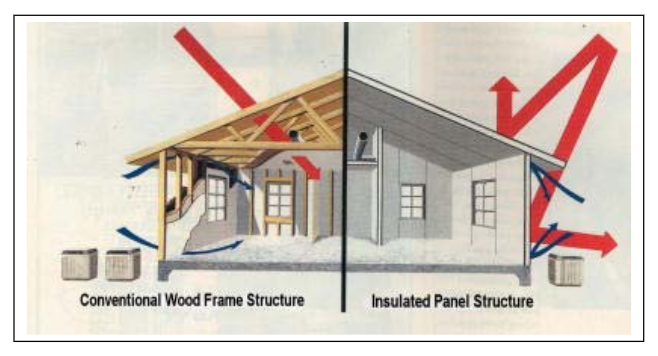

Further Cost Savings

Reduced drywall cracking as house settles less with SIPS panels

Half the amount, if not more, of left over lumber waster material

Energy saving for home owner

Finish trades require less time dealing with bowed walls (Tile, Cabinets)

A possible reduction in crane rental time when using roof panels instead of trusses

A possible reduction in hardware, such as hold downs, when using wall panel

Sip panels will typically cost about five percent more than conventional framing

Frame Cost

Per builder/architect Lance O’Donnell framing costs usually run between 20% and 30% of building costs. We will use 25% for an average.

| $110.00 per sq. ft. time 2500 sq. ft. = | $275,000 | |

| Divided by 25% for framing costs = | $68,750 | ($27.50 sq. ft.) Timber Framing |

| $115.50 per sq. ft. time 2500 sq. ft. = | $288,750 | |

| Divided by 25% for framing costs = | $72,187.50 | ($28.88 sq. ft.) SIPS |

Per Unit

| Framing cost for SIPS | $72,187.00 (25% of overall cost) |

| Framing cost for Timber Frames | $68,750.00 (25% of overall cost) |

| Difference in framing costs | $ 3,437.50 (per unit) |

Building Cost

| $278,437.50 | (cost with SIPS) |

| $275,000.00 | (cost without SIPS) |

| $ 3,437.50 | (difference is framing cost) |

| $ 3,440.00 | (savings in labor and materials as above) |

| $ (2.50) | (breaking even) |

| $ (1,200.00) | (down sizing from a 5 ton to a 3 ton HVAC unit) |

| $ (1,202.50) | (down sizing from a 5 ton to a 3 ton HVAC unit) |

| $ (700.00) | (savings in wasted lumber plus handling) |

| $ (1,902.50) | (overall savings per unit) |

Approximate money saved for multiple homes

| $1,902.50 per unit time 10 units = | (profit to builder) | $19,025.00 |

| $1,902.50 per unit time 50 units = | (profit to builder) | $95,125.00 |

| $1,902.50 per unit time 100 units = | (profit to builder) | $190,250.00 |

| $1,902.50 per unit time 200 units = | (profit to builder) | $380,500.00 |